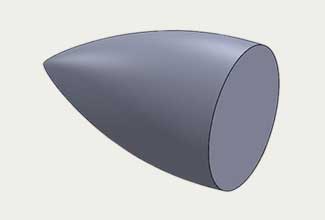

FRP Aerospace Parts

FRP (Fiber Reinforced Polymer) aerospace parts are advanced composite components used extensively in the aerospace industry due to their exceptional strength-to-weight ratio, corrosion resistance, and durability. These parts are manufactured by reinforcing a lightweight polymer matrix—such as epoxy or polyester—with high-performance fibers like carbon, glass, or aramid (e.g., Kevlar). FRP aerospace components are commonly used in structural elements such as fuselage panels, wing sections, fairings, and control surfaces, as well as in interior parts like seat structures and cabin panels. The primary advantage of using FRP in aerospace is the significant weight reduction compared to traditional metals, which improves fuel efficiency and overall aircraft performance. Additionally, FRP materials offer excellent fatigue resistance and design flexibility, enabling the production of complex shapes with fewer joints or fasteners. As aerospace applications demand high precision and reliability, FRP parts are often produced under strict quality standards using advanced processes like autoclave curing, resin transfer molding (RTM), and filament winding. These composites not only enhance performance but also contribute to the sustainability goals of modern aviation by lowering emissions through weight savings.